Amprius Technologies, a producer of 100% silicon anodes for Li-ion batteries (earlier post), announced a contract award with the US Army’s Rapid Capabilities and Critical Technologies Office (RCCTO). The contract, an 18-month rapid prototyping effort, includes the design, development, and validation of high-energy-density lithium-ion batteries to be used in unmanned aircraft system (UAS) applications such as drone systems used by the US Army.

With the surge of increasingly hostile and lethal battlefields, new technologies—including reconnaissance drones—are being deployed on a regular basis to help ensure safety. To be effective, the drones must be lightweight enough to be easily carried onto the field and provide enough flight time to complete mission objectives. This is nearly impossible with conventional batteries that are both heavy and offer limited flight time capabilities.

Amprius’ proven superiority in specific energy and energy density with Si-Nanowire allows us to enable unprecedented performance in drones, effectively doubling the operational endurance of UAS.

—Ionel Stefan, Chief Technology Officer of Amprius Technologies

Using Amprius’ Silicon Nanowire technology, US military forces will be enabled with nearly 100% increased battery performance, doubling the run-time for all mobile-powered devices.

The Army Rapid Capabilities and Critical Technologies Office’s mission is to rapidly and efficiently research, develop, prototype, test, evaluate, procure, transition, and/or field critical enabling technologies and capabilities that address near-term and mid-term threats. The Office will produce or acquire materiel solutions consistent with the Army’s modernization priorities that maximize soldiers’ capabilities to deploy, fight, and win on future battlefields.

Amprius is the only company to offer a 100% silicon anode Li-Ion battery commercially. Providing the highest energy density and specific energy in commercially available cells, Amprius’ Si-Nanowire platform will be used in UAS, UAM, and eVTOL applications globally. Based on an Armstrong & Associates market study, Amprius estimates the total battery market for UAS to be more than $10 billion and increasing to more than $30 billion by 2024.

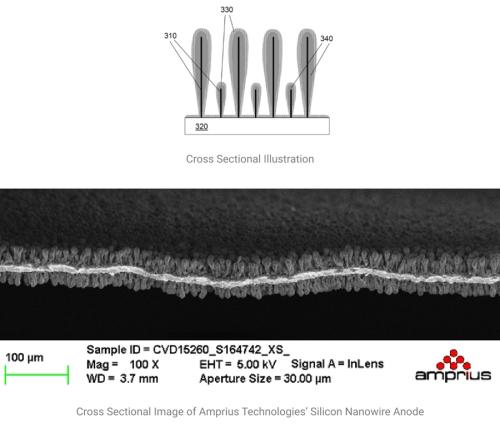

In 2007, Stanford University researchers discovered that silicon nanowires tolerated swelling and resisted cracking—well known problems with silicon anode materials. Amprius perfected this technology; its 100% silicon nanowire anode is a direct replacement for graphite anodes. The rest of the battery components and manufacturing methods leverage the established global supply chain for lithium-ion batteries.

The silicon nanowires are connected directly to the substrate with no binders, meaning that there is nothing to block the flow of current.