France-based specialty chemicals and materials company Arkema announced a 50% increase in its Kynar PVDF fluoropolymer production capacities at its Pierre-Bénite site in order to address the fast-growing demand for materials for lithium-ion batteries. Arkema now aims for sales of at least €1 billion in the battery sector by 2030.

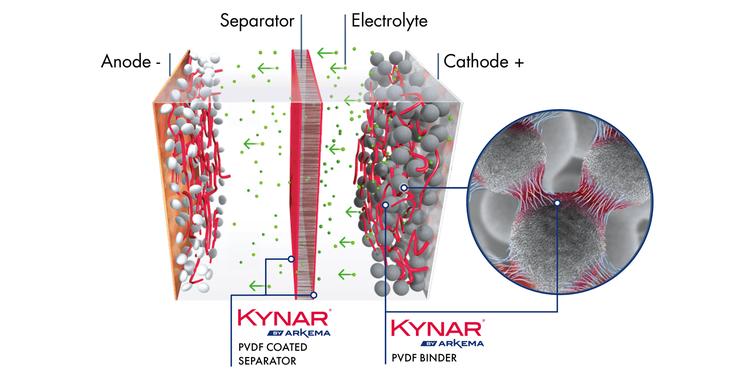

In Li-ion batteries, the Kynar PVDF polymers are used as separators coatings or as cathode binders. New innovations and product ranges will also be offered, such as Kynar CTO, a new Kynar PVDF made from renewable sources. This new extension should come on stream in the first quarter of 2023.

Arkema is one of the world’s leading suppliers of high-value-added solutions for batteries: PVDF for binders and separator coatings; lithium salts to improve cell performance; smart adhesives for cell-to-cell bonding; and bio-based polyamide 11 to cool battery lines.

The company has opened a new Center of Excellence dedicated to batteries for clean mobility that is equipped with state-of-the-art design and analysis equipment, including a dry room and an electrode coating line. It draws on the scientific and technical complementarity of the Pierre-Bénite Research Center’s researchers.

This Center of Excellence, which will help accelerate the development of advanced materials and processes for future generations of more efficient, safer and more compact batteries, was partly financed by the Région-Auvergne-Rhône-Alpes.

Alongside this platform, a pilot line dedicated to the pre-industrialization of the next generations of electrolytes for the batteries of the future is already operational.

The teams will conduct research with the Group’s academic partners (CNRS, CPE in Lyon, LEPMI in Grenoble and ENSCM in Montpellier), as well as with partners in the battery ecosystem, with which strategic agreements have been concluded (start-ups, manufacturers, gigafactories).

This investment benefited from support from the government of France as part of the “France Relance” plan.